Switzerland boasts some of the best technical universities in Europe, and one of the most attractive business environments on the continent. As a country long known for its enviable business ethic and support for entrepreneurialism, Switzerland is increasingly becoming one of Europe’s top destinations for technology start-ups.

European CEO spoke to Felix Beyeler, CEO of growing Swiss start-up firm FemtoTools, to gain a better understanding of Switzerland as a leading start-up hub in Europe, and his firm’s work. FemtoTools is a developer and provider of high-precision robotic instruments, and is set to play an increasingly important role in the current boom in miniaturised and nano robotics. FemtoTools’ technology started as a university research project, and now boasts customers from across Europe, as well as North America and Asia. FemtoTools hopes to further develop its micro and nano products, while at the same time growing its customer base internationally.

Tell us about the start-up scene in Switzerland and the ways in which you’ve seen it evolve

Switzerland is a great country to work and to live in. It is also known to be one of the most innovative countries in the world, mostly due to all the patents submitted by pharmaceutical giants. However, even though the local start-up scene is very lively and spread across the whole country, Switzerland is probably not seen as a big international start-up hub as of yet. Currently, I have the impression that there are a lot of great new business ideas coming from the students working at the two big technical universities in Zurich and Lausanne. I think that the great financial success of the ‘geeks’ from Silicon Valley has also inspired students in Switzerland to become entrepreneurs.

The great financial success of the ‘geeks’ from Silicon Valley has also inspired students in Switzerland to become entrepreneurs

How does the market for start-ups in Switzerland differ to that of neighbouring European nations?

Swiss start-ups put a lot of effort and time into creating a high-quality product or service. Local start-ups and investors are typically very careful, and plan everything very extensively. This results in an exceptionally high survival range compared to other countries. However, this Swiss carefulness and modesty comes with the disadvantage of slower company growth and a low number of really big exits.

Can you explain the importance of ultra-high-precision instruments in the micro and nano domain?

In many markets, such as consumer electronics, semiconductor manufacturing or medical instrumentation, there is an ongoing trend towards miniaturisation; it enables products that are more affordable, have additional capabilities and feature a smaller footprint. Therefore, miniaturisation is widely accepted as a positive step in product development. However, for the development, assembly and quality control of miniaturised components, novel equipment is required that can work in micrometres (one micrometre is 0.001mm). As a comparison, the diameter of a human hair is about 80 micrometres.

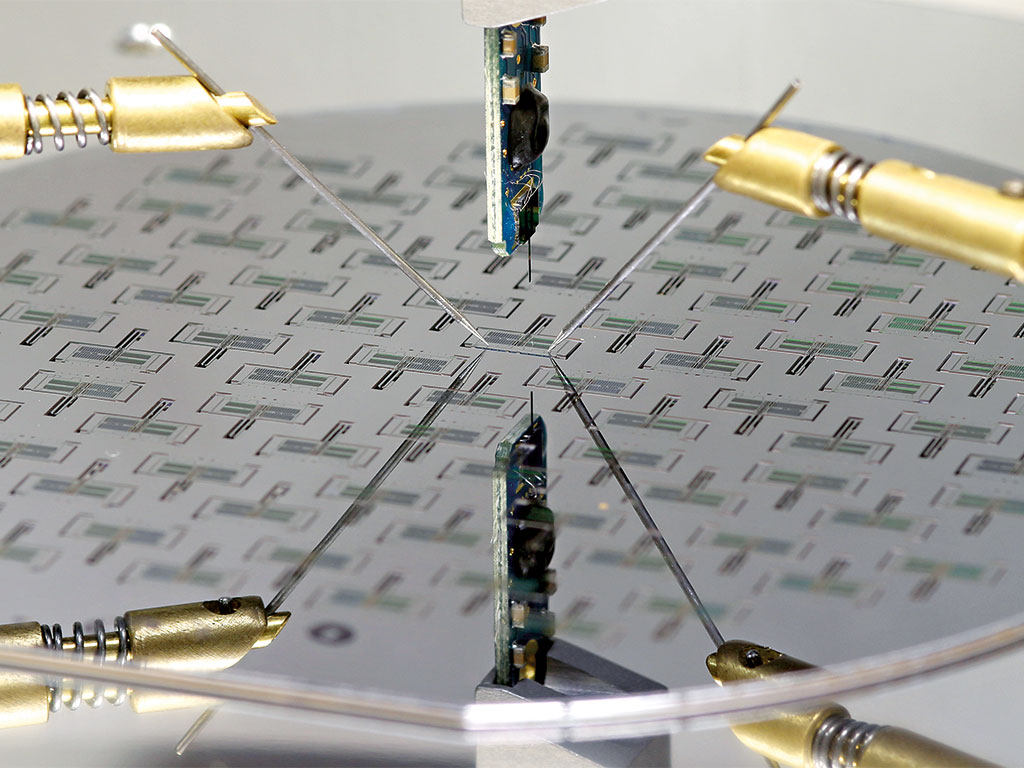

FemtoTools is a developer and provider of high-precision robotic instruments for the testing and handling of miniaturised components. Our instruments are used in R&D by academic and industrial research facilities, and for quality control in high-tech companies. We help our customers to reduce R&D costs and production costs, and increase the reliability of their products.

What are the geographical and technical challenges of providing instruments to a fragmented market?

Micrometre-sized components can be found in multiple market segments, which are very different from each other. To give you an example, the requirements of the chip manufacturing industry are very different from the requirements of an academic research laboratory studying cancer cells (biological cells are micrometre-sized structures as well). We are dealing with this technical challenge by providing modular products that can be reconfigured for different applications. This is very important to our company, since we are an instrument supplier and we do not want to become an engineering service company. The instruments supplier strategy allows for a faster scaling and growth of our company.

The requirements of the chip manufacturing industry are very different from the requirements of an academic research laboratory studying cancer cells

Apart from the technical fragmentation, there is also a high level of geographical fragmentation. Our customers are spread all over the world. Most of them are located in Europe, North America and Asia. One of the biggest challenges is to build an efficient network for sales and support for our international customers. Our strategy is to employ skilled experts who can understand the technical challenges and projects of our customers. Also, we are working with a small number of carefully selected distribution partners to support our customers in Asia and in North America.

What is driving the miniaturisation trend in robotics?

Traditional manufacturing methods such as milling, drilling and screwing parts together do not work at the micro scale any more. New technologies such as micro electro mechanical systems (MEMS) have allowed products to become even smaller.

MEMS are fabricated by wafer processing, similar to the chip-manufacturing processes used by the semiconductor industry. The next big miniaturisation step will be the transition from microsystems to nanosystems; this is a great technical challenge, but also a great opportunity. It is what is driving for the robotics field to make the transition from microrobotics to nanorobotics.

How did FemtoTools change from a university research project into a company?

Before the company was established, my colleagues and I worked as researchers at ETH Zurich, the biggest technical university in Switzerland, in the field of microrobotics. Our research project was successful, and the results have been published in scientific journals. After that, other researchers from different research fields that wanted to collaborate and use our technology for their research projects frequently contacted us. This was very exciting, but we did not have the time to work with most of them. During that time, we came up with the idea of commercialising the technology that we developed. When we founded FemtoTools, we were in the comfortable situation of already having customers waiting to get their hands on our products.

What are your plans for the future?

We are a relatively small company that is growing fast. This means that we have to allocate our resources in the most efficient way. We are in a very early-stage market, which means there is a lot of growth potential. Our current focus is to strengthen our international sales channels and investigate additional market niches that are currently untouched. There are a lot of exciting opportunities and we have tons of ideas. The plan for the future is to go smaller on the technical side and go bigger on the business side.